Our Setup

Here in Yeshwant Castings, latest technology is used and sophisticated software like CAD/CAM along with state-of-the-art techniques enables to design and manufacture products to the highest standards. The company offers a full design service and comprehensive products to any of our customers who have non standard requirements.

Heat treatment

Heat treatment

The heat treatment of castings produced by the company involves the third party materials and well-organized stages of manufacturing. From full anneal to remove traces of chill and hardness, improving machinability, stress relieve, to reduce or remove the tendency to warp in machining or later life. Austempering to produce a very hard wearing component, which is best carried out after initial machining. the final process has to use grinding procedures.

Machining

Machining

Castings can be provided in a proof or finished machined condition, subassembly operations can be undertaken.

Painting

Painting

It can be carried out immediately after shot-blasting which includes red oxide, admiralty grey, black primer or customized specification according to customers need.

Delivery

Delivery

Prompt delivery is important criteria for our service. Transport is provided by local as well as national carriers either overnight or 3 day standard. International destinations are covered by the most suitable carrier. Alternatively you can arrange for your own collection. Prices are quoted ex-works.

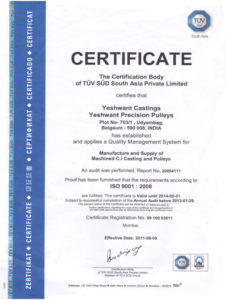

Quality Policy

Quality Policy

Yeshwant Castings aims to achieve Total Customer satisfaction by manufacturing and Supplying Machined Castings and Pulleys meeting customer’s requirements of Quality, Ontime Delivery and value. We will focus on continuous improvement through Technology upgradation, efficient supply management, Training of our Human Resources and improving our systems and processes at all levels in our organization.